A Guide to Repairing Electronics: PCB Testing and Faulty Component Tracing

A Guide to Repairing Electronics: PCB Testing and Faulty Component Tracing

Introduction:

Briefly introduce the importance of repairing electronics.

Mention the significance of testing PCBs to find faulty components.

Section 1: Safety Precautions

Emphasize the importance of safety while working with electronics.

Highlight the need for proper tools and equipment, including ESD protection.

Section 2: Initial Inspection

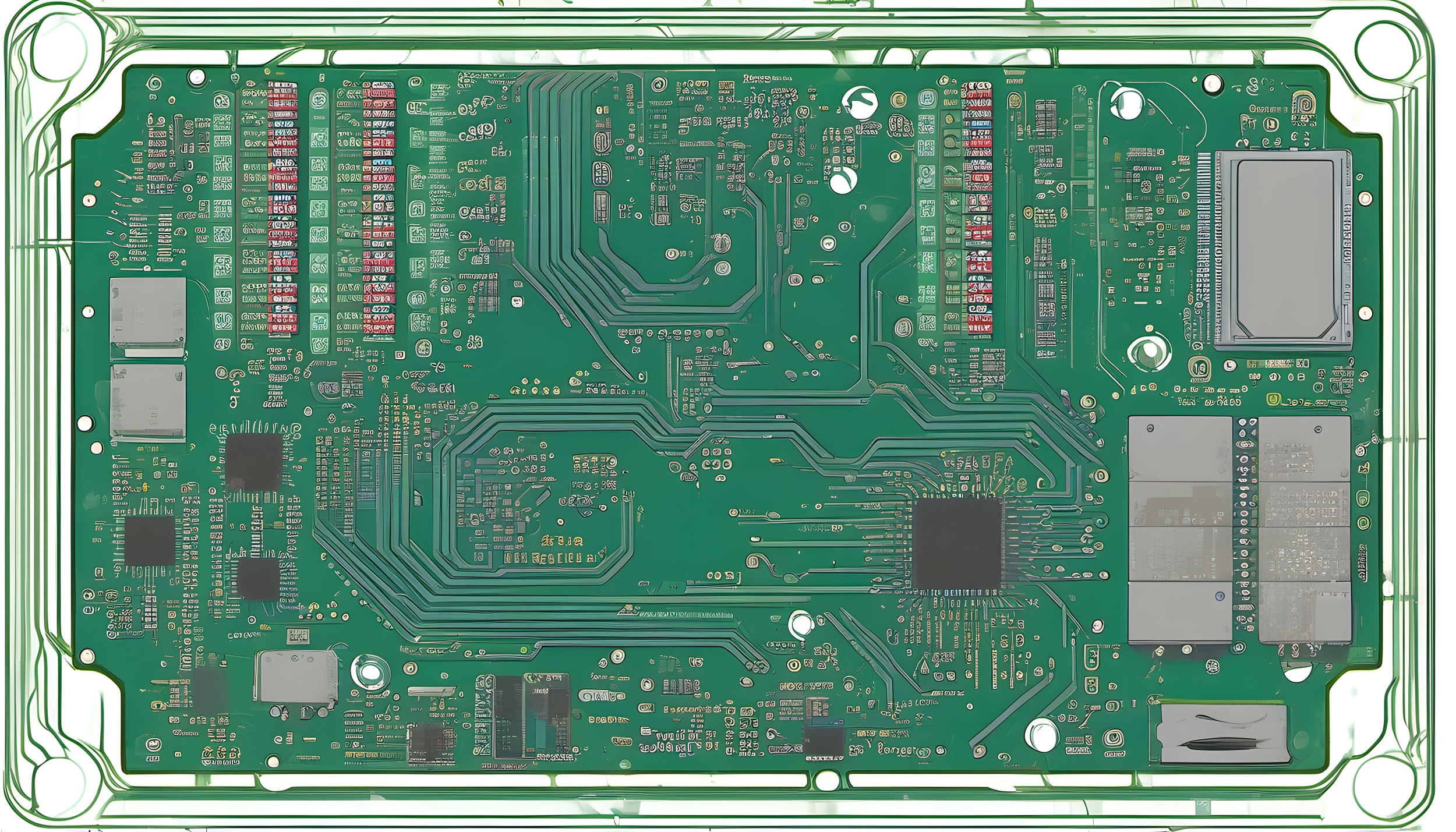

Discuss the importance of a visual inspection of the PCB.

Look for physical damage, burnt components, loose connections, and signs of corrosion.

Section 3: Power Supply Testing

Explain the significance of testing the power supply.

Describe how to use a multimeter to measure voltage and current.

Check for correct voltage levels and continuity.

Section 4: Component Testing

Detail how to test individual components like resistors, capacitors, diodes, and transistors.

Explain the use of a multimeter and other specialized testing equipment.

Highlight common component failure signs and how to identify them.

Section 5: Tracing Faulty Components

Discuss the process of elimination to trace the faulty component.

Explain the importance of systematic testing and documentation.

Provide tips for isolating the problematic area on the PCB.

Section 6: Soldering and Desoldering

Cover basic soldering and desoldering techniques.

Explain how to replace faulty components.

Emphasize the importance of precision and clean soldering.

Section 7: Common Troubleshooting Scenarios

Discuss some common issues and how to approach them.

Offer solutions for specific problems like no power, audio issues, or display problems.

Conclusion:

Summarize the key steps in testing and tracing faulty components on a PCB.

Encourage readers to be patient, methodical, and safety-conscious.

Remember, this is just an outline, and a full article would require more in-depth information for each section. You may want to consider additional details, illustrations, and practical examples for a comprehensive guide on repairing electronics.

· When troubleshooting electronics with no power, start with the following steps:

Check the Power Source:

Ensure that the power source (e.g., power cord, batteries) is functional and properly connected.

Verify that the power outlet or source is active and providing the correct voltage.

Inspect Fuses and Circuit Breakers:

Look for blown fuses or tripped circuit breakers in the device or within its power supply circuit.

Replace any blown fuses with the correct rating.

Test Power Supply Unit:

Use a multimeter to measure the output voltage of the power supply unit (PSU).

Verify that the PSU is providing the correct voltage and that it is operational.

Check Power Switch and Connections:

Inspect the power switch for any physical damage or disconnection.

Ensure that the connections between the power switch and the PCB are intact.

Inspect for Short Circuits:

Look for signs of short circuits on the PCB, such as burnt or damaged components.

Examine the PCB for loose wires or traces that may be shorted.

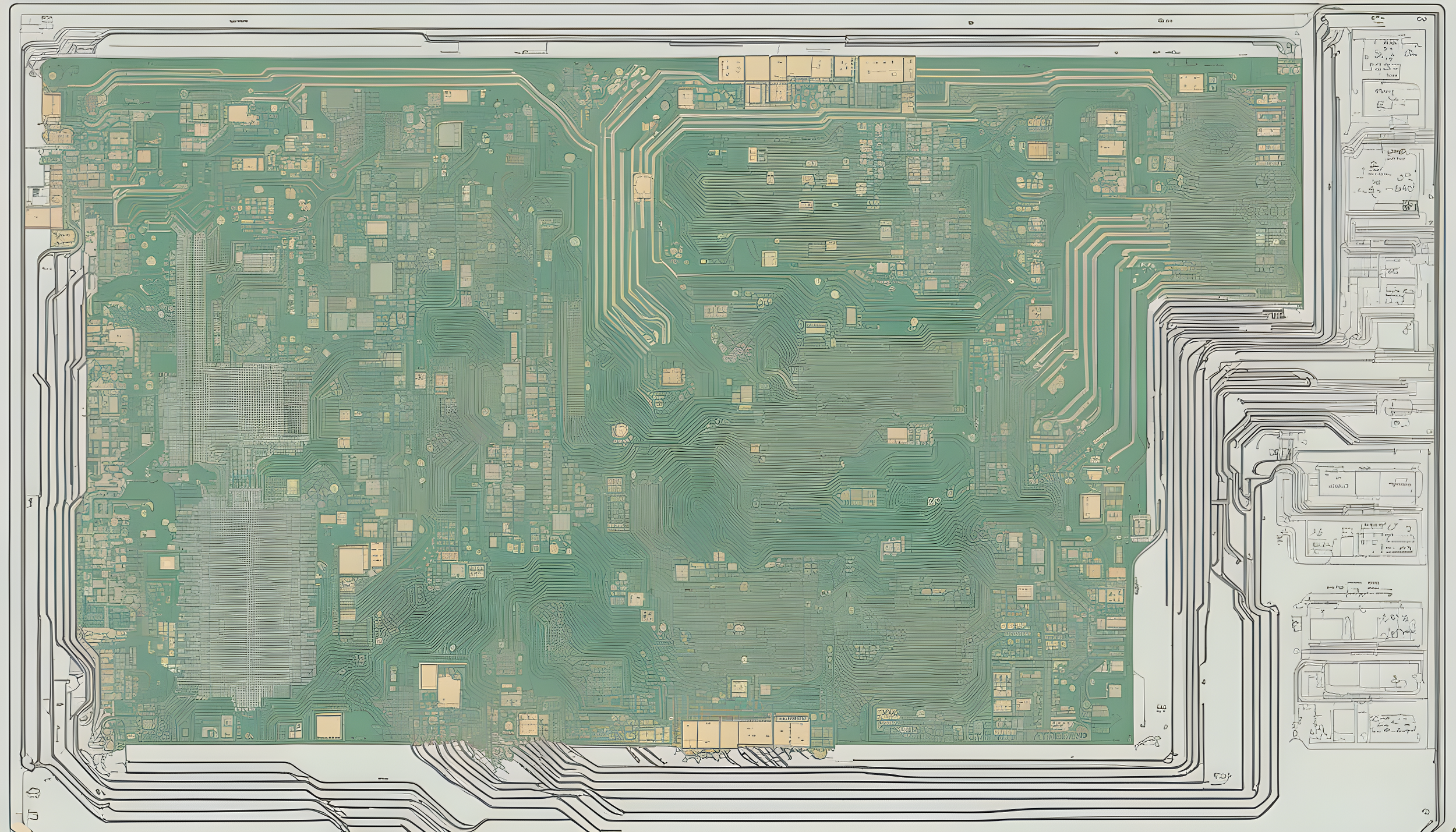

Test Power Distribution:

Trace the power path on the PCB to identify where the power is lost.

Use a multimeter to measure voltage at various points along the power path to locate the issue.

Capacitor and Diode Check:

Test capacitors for leakage or bulging.

Check diodes for continuity or signs of failure.

Visual Inspection:

Carefully examine the PCB for any visible damage, burnt components, or loose connections.

Reset or Clear Faults:

If the device has a reset button or procedure, follow the manufacturer's instructions to reset it.

Check for any fault codes or indicators that might provide clues about the issue.

· By systematically following these steps, you can identify the source of the power problem and work towards repairing the electronics with no power. Keep in mind that proper safety precautions should always be observed when dealing with electronics.

If there's no fault in the power supply, but the PCB still has no power, you'll need to dig deeper into the diagnosis. Here are some additional steps to consider:

Inspect the Power Distribution:

Examine the entire power distribution network on the PCB, from the power input to the components that should receive power. Look for any damaged traces, broken connections, or burnt components.

Check for Short Circuits:

Use a multimeter in continuity mode to check for short circuits on the PCB. Look for any unexpected connections between different parts of the circuit that shouldn't be connected.

Component Testing:

Test key components such as voltage regulators, ICs, and transistors. Check for proper voltages at the input and output of these components.

Look for any components that are overheating, which can indicate a short circuit or a faulty component.

Visual Inspection:

Carefully inspect the PCB for any physical damage or corrosion that may not be immediately obvious.

Look for any loose solder joints or connections.

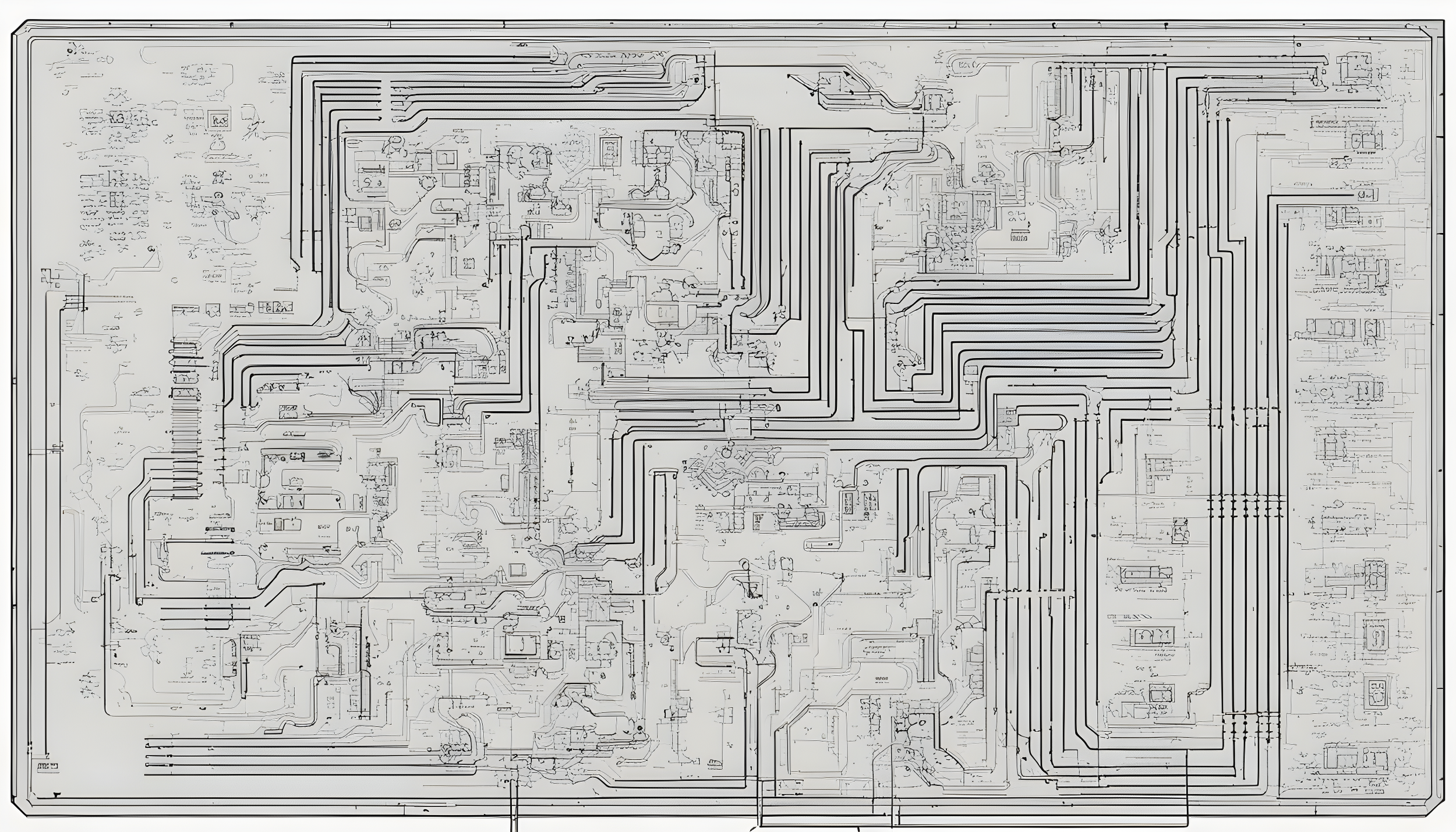

Schematic Analysis:

If you have access to a schematic diagram of the circuit, use it to trace the power flow and identify critical components and connections.

Compare the actual circuit to the schematic to pinpoint any discrepancies.

Oscilloscope Use:

Use an oscilloscope to analyze waveforms and signals at various points in the circuit. This can help identify anomalies or irregularities in the signal path.

Swap or Replace Components:

If you suspect a specific component is faulty, consider swapping it with a known working one to see if the problem is resolved.

Gradually replace components or subcircuits to narrow down the issue.

Firmware or Microcontroller:

If the device is controlled by a microcontroller, check if the firmware is functioning correctly.

Test the microcontroller or microprocessor for signs of life and proper operation.

Professional Help:

If you're unable to identify the issue after thorough troubleshooting, consider seeking professional assistance, especially for complex or sensitive devices.

Remember, diagnosing a PCB with no power can be a challenging task, and it often requires patience and systematic testing. If the issue still remains elusive, consulting a professional technician or engineer with expertise in electronics repair may be the best course of action. Let us help you at T-Bone Electronics: Contact us Here.